STAIR-CASES HUIZEN

a

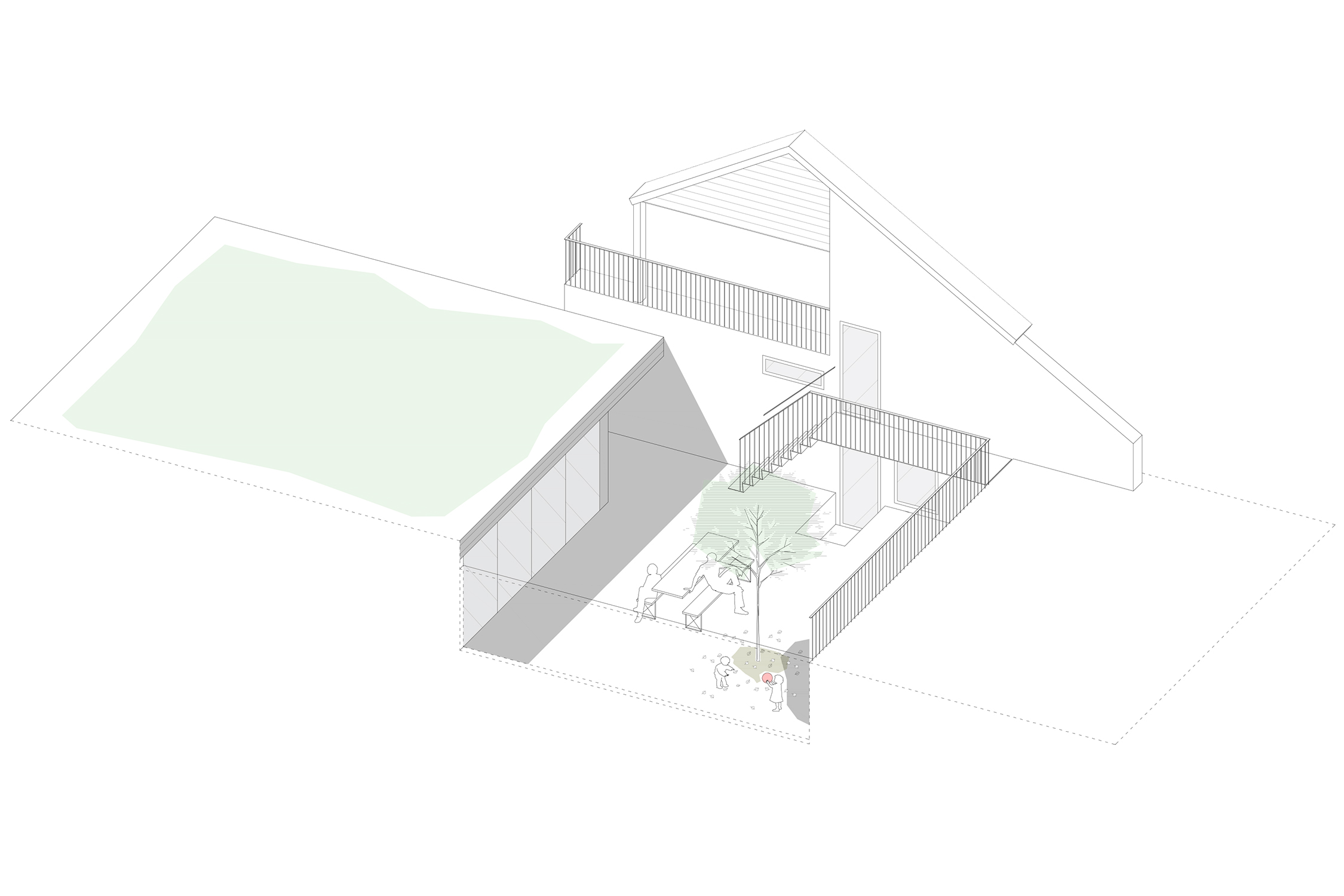

This house in Huizen, East of Amsterdam, has been built in 1977 located in an old loam pit with a difference in ground level between the street and part of the garden as a result. This was incorporated into the original design of the house by adjusting half of the house to the street level and the other half to the garden level (split-level). The main need underlying the project, formulated by the clients, is to find ways to afford access to the different floor levels by providing stairs and balustrades. Both in the interior and the exterior of the house, providing safety for their grantchildren. Emphasis is on connecting the interior and the surrounding garden through the use of natural materials.

Exterior,

a

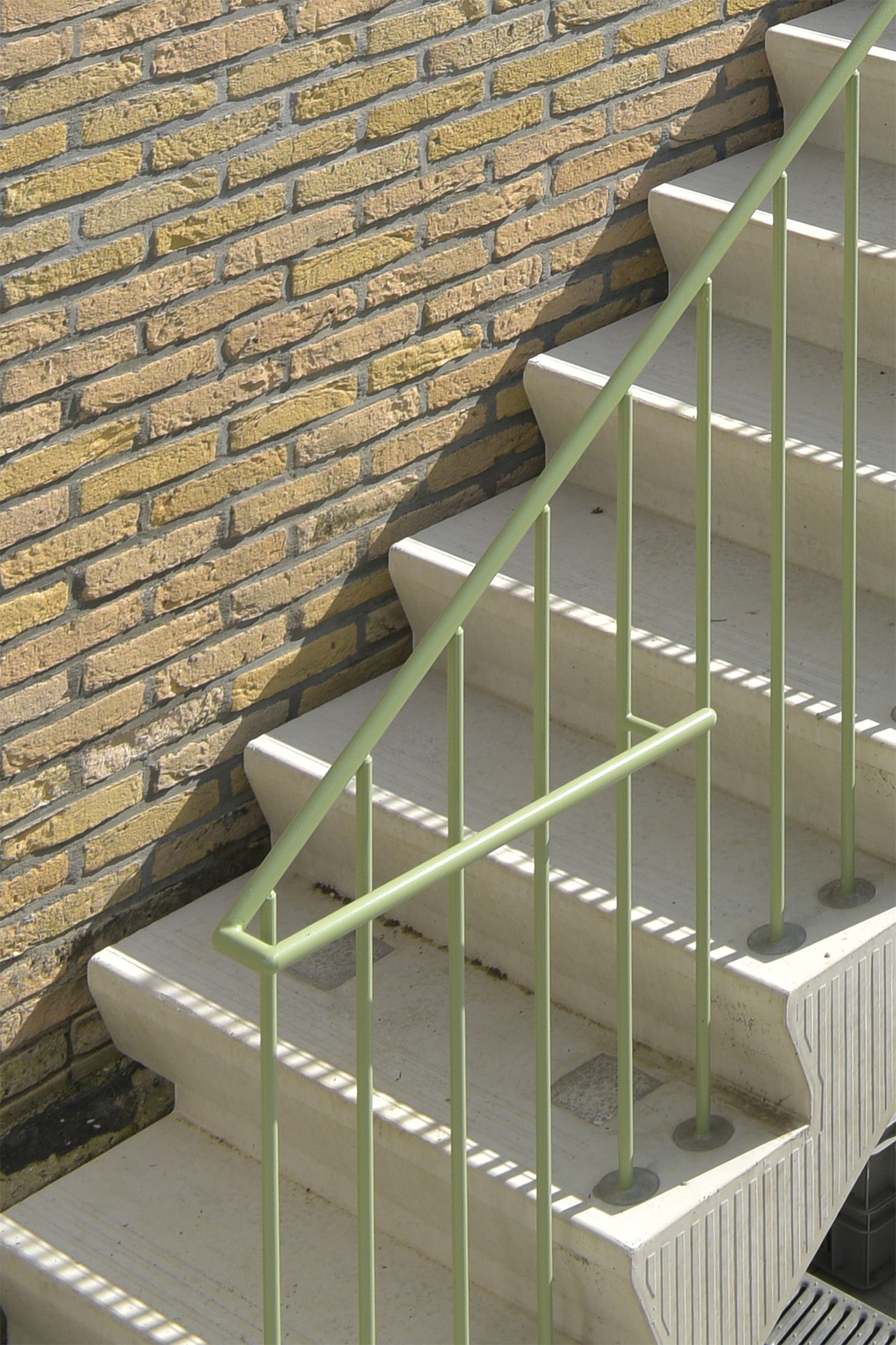

The former garage has been transformed into a guest house and workspace adjacent to a courtyard-like exterior space were the driveway used to be. From the main house there are two doors that lead onto this courtyard, one from the basement and one from the kitchen at street level. To make the latter accessible a walkway with stairs is provided that connects the parking-lot, kitchen and garden in one movement. In line with the materials used for the structure of the house, brick walls and concrete floors, a stony material was chosen again for this new walkway. The concrete structure is prefabricated and assembled on site. A slender steel balustrade is incorporated in the concrete structure following its shape. The walkway is finished with deck made of chestnut from Italy. This will slowly wheather and turn grey and is one of the possible alternatives to the common tropical hardwood types used for decking.

Along the rear facade there's a large balcony adjacent to the living space of which the previous balustrade no longer provided for safe access. Concrete, steel and chestnut find there way here in slightly different detailling. At the edge of the balcony concrete elements have replaced the zinc, and on top of the roofing a chestnut deck is placed with a steel balustrade in between the two combined with roof vegetation.

Since the garage has found a new use the need for a storage and some fencing arose. A shed and a fence are made of douglas timber from The Netherlands, to connect the timber structural parts stainless steel details were developend and produced in collaboration with the structural engineer and smith. Steel roofing was applied for the shed. The timber remains untreated and will gradually wheather and turn grey. Both the shed and the fence were made in collaboration with the client.

Interior,

a

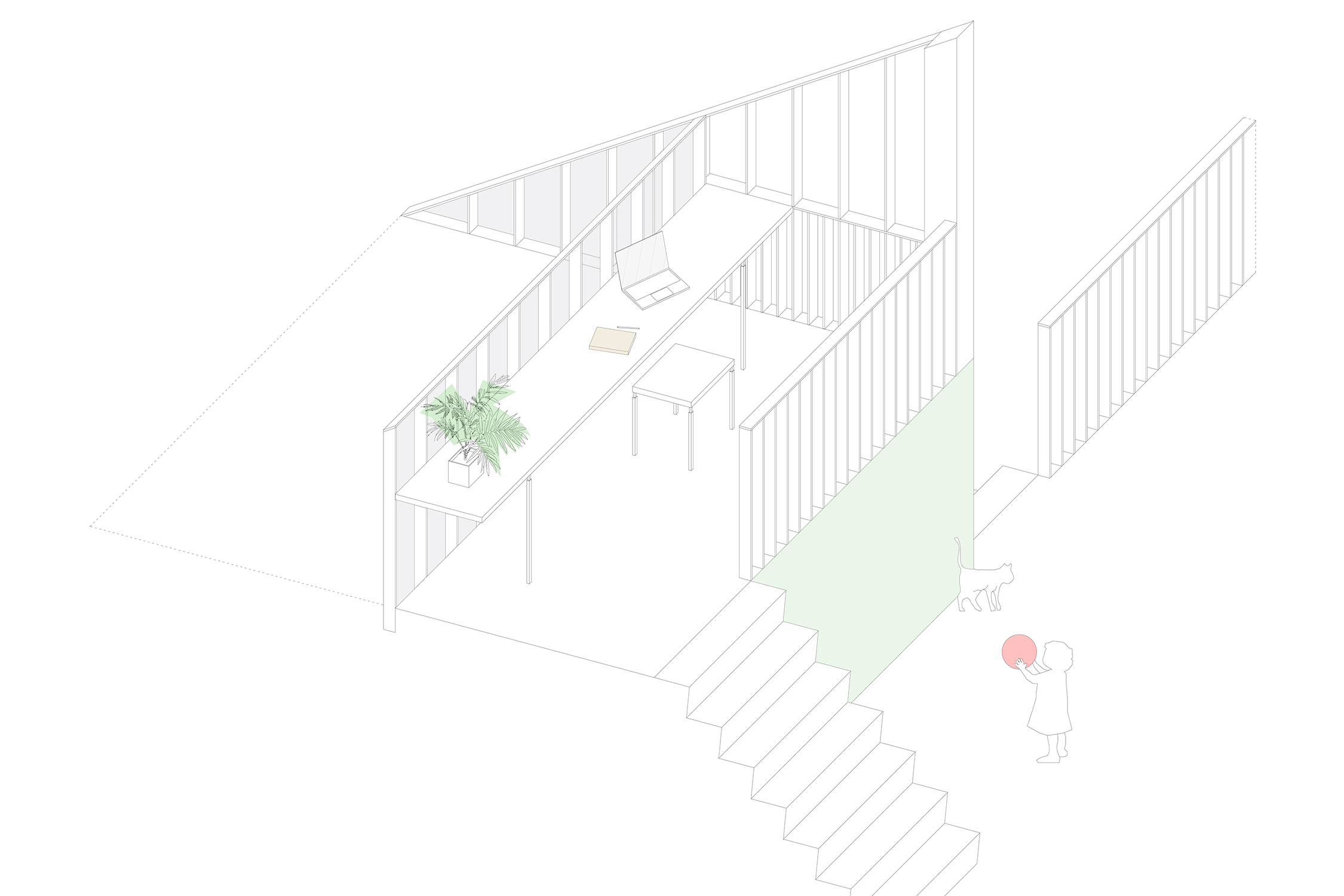

The brick currently still visible in the exterior facade used to be visible in the interior as well, in masonry balustrades separating the different floor levels and in intermediary walls. Because of this the different parts of the living area were visually separated. A big decision the clients made was to take down these separations and to place eight big sky lights through which an abundance of natural day- and sunlight enters the living spaces.

The only additions to this light and open living area are different elements made of elm wood: balustrades, stairs, handrails and a worktop. Besides the practical solutions these elements provide for safety and accessibility of the five different floor levels in the house, it also provides a small study. The elm wood is chosen for its warm atmosphere, subtle contrast with the flooring and keeping in mind the different shades of green in the furniture. It has been applied combined with brass and blue steel details. The wooden sections of the balustrade were shaped to have a minimal size seen from the front so that the view from interior to exterior is not limited more than necessary. Seen along the balustrade the depth of the section does the opposite were it limits the view to define different areas within the main living space.

Design, supervision and realisation by Rogier Rouwet.

Steel balustrades and details by Joost Bosman of Smederij Bosman.

Cast-in-situ foundations and assembling prefabricated concrete by Willem van der Straten of Bouw en Montagebedrijf van der Straten.

Elm wood in the interior by Wim and Timon Bongers of Meerkat Meubels.

Structural advice by Wim Wieskamp of SEM Oost Nederland.

Prefabricated concrete parts by HCI Hengelo.

Roofing by Dakdekkersbedrijf Poppe.

a

Thanks to Annelies Gieling and Hans Burggraaff.